-

Receb클라이언트는 그들이 당신의 이전 생산을 가진 결과에 기뻤기 때문에 당신을 그들의 제품을 생성하는 원합니다.

Receb클라이언트는 그들이 당신의 이전 생산을 가진 결과에 기뻤기 때문에 당신을 그들의 제품을 생성하는 원합니다. -

Sean좋은 팀웍 – 좋은 공급자, 빠른 활동 및 협력하는 양측에 좋은 사람들…. 감사합니다.

Sean좋은 팀웍 – 좋은 공급자, 빠른 활동 및 협력하는 양측에 좋은 사람들…. 감사합니다. -

Chris반작용할 것이다 충분히 걱정을 위한 감사합니다는, 다르게 생각하고 저희와 – 여기에서 다시 이 기회에 매우 RnD에서 저희에게서 평가된 이 대안을 – 찾아내기 위하여 혁신합니다,

Chris반작용할 것이다 충분히 걱정을 위한 감사합니다는, 다르게 생각하고 저희와 – 여기에서 다시 이 기회에 매우 RnD에서 저희에게서 평가된 이 대안을 – 찾아내기 위하여 혁신합니다,

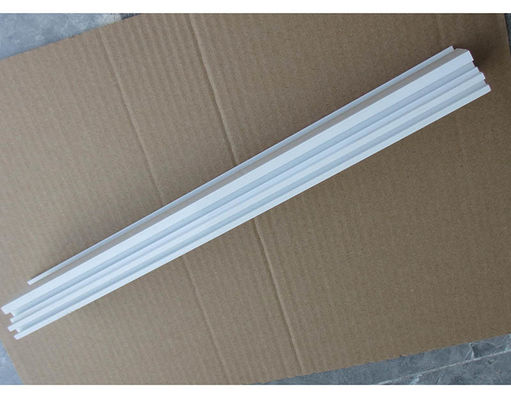

Professional Injection Molding Service with Pro/E AutoCAD and Solidworks Design Software for Precision Plastic Fabricating

무료샘플과 쿠폰을 위해 나와 연락하세요.

WhatsApp:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 표면 마감 | 끝마무리, 그림, 실크-스크린 프린팅, Etc. | 디자인 소프트웨어 | UG, Pro/E, 오토캐드, 솔리드웍스 |

|---|---|---|---|

| 포장 | 나무 상자, 통, 팔레트 | CNC 가공 | 예 |

| EDM 기계가공 | 예 | 서비스 유형 | 사출 성형 서비스 |

| 곰팡이 공동 | 단일 공동, 멀티 캐비티 | 곰팡이 수명 | 500,000-1,000,000 샷 |

| 강조하다 | Pro/E Design Software Injection Molding Service,AutoCAD Design Software Injection Molding Service,Solidworks Design Software Plastic Fabricating Service |

||

Product Description:

Injection molding services offer a versatile solution for the production of a wide range of plastic parts. Utilizing cutting-edge technology and a team of skilled professionals, these services provide efficient and cost-effective manufacturing processes for various industries. One of the key features of this service is the incorporation of CNC machining, allowing for precise and complex designs to be translated into high-quality plastic components. The materials used in injection molding services include ABS, PP, PC, PA, POM, PMMA, and other thermoplastics. These materials offer a diverse range of properties, such as durability, flexibility, and heat resistance, making them suitable for a variety of applications. In addition to thermoplastics, thermosetting materials can also be utilized in the injection molding process, expanding the possibilities for creating specialized components. Design software plays a crucial role in the injection molding process, enabling the development and visualization of intricate part designs. With software options like UG, Pro/E, AutoCAD, and Solidworks, engineers can create detailed 3D models and optimize part geometries for efficient production. This integration of design software ensures the accuracy and consistency of the manufactured parts, meeting the specific requirements of each project. When it comes to mold cavity configurations, injection molding services offer the flexibility of single cavity and multi-cavity molds. Single cavity molds are ideal for low-volume production or large, complex parts that require individual attention. On the other hand, multi-cavity molds enable the simultaneous production of multiple parts, increasing efficiency and reducing overall production time. This versatility in mold cavity options allows for customization based on production volume and part complexity. The service type provided by injection molding services encompasses a wide range of capabilities, including prototyping, short-run production, and high-volume manufacturing. Whether it's a small batch of custom parts or a large-scale production run, these services can accommodate various project requirements with precision and consistency. From concept to final product, injection molding services offer a seamless process that ensures quality and efficiency at every stage. In summary, injection molding services offer a comprehensive solution for the production of plastic components, utilizing advanced technology and expertise to deliver high-quality results. With CNC machining, a wide range of materials, sophisticated design software, and flexible mold cavity options, these services cater to diverse industry needs. Whether it's thermoplastic or thermosetting molding, injection molding services provide a reliable and efficient manufacturing solution for a variety of applications.

Technical Parameters:

| Tolerance | ±0.01mm |

| CNC Machining | Yes |

| Packaging | Wooden Case, Carton, Pallet |

| Surface Finish | Polishing, Painting, Silk-screen Printing, Etc. |

| Design Software | UG, Pro/E, AutoCAD, Solidworks |

| Mold Life | 500,000-1,000,000 Shots |

| Mold Base | LKM, HASCO, DME |

| Mold Cavity | Single Cavity, Multi-Cavity |

| Inspection | CMM, Projector, Caliper, Microscope, Etc. |

| Shipping | Sea, Air, Express |

Applications:

When it comes to injection molding services, OEM is a trusted brand that originates from China. With ISO90001 certification, OEM offers high-quality services tailored to meet diverse needs.

The product application occasions and scenarios for the injection molding services provided by OEM are vast and varied. One common application is in the manufacturing of plastic components for various industries such as automotive, electronics, consumer goods, and medical devices. The versatility of materials used, including ABS, PP, PC, PA, POM, PMMA, and more, allows for the production of a wide range of products.

Whether you require thermoplastic molding service, injection moulding service, or thermosetting molding service, OEM can cater to your specific requirements. The design software proficiency in UG, Pro/E, AutoCAD, and Solidworks ensures precise and accurate mold designs.

With a minimum order quantity of 1 set and flexible pricing options through negotiation, OEM makes it easy for businesses of all sizes to access their injection molding services. The packaging details on metal pallets ensure safe transportation of the molds to their destination.

Customers can expect a delivery time of 45-50 days, with payment terms available via T/T. The supply ability of 10 sets per month showcases OEM's commitment to meeting customer demands efficiently.

Inspection processes using CMM, Projector, Caliper, Microscope, and other tools guarantee the quality and precision of the molds. The lead time of 15-30 days further emphasizes the speed and efficiency of OEM's service.

Customization:

Product Customization Services:

- Brand Name: OEM

- Place of Origin: China

- Certification: ISO90001

- Minimum Order Quantity: MOQ 1 set

- Price: Negotiation

- Packaging Details: Metal Pallets

- Delivery Time: 45-50 days

- Payment Terms: T/T

- Supply Ability: 10 Sets per month

- Service Type: Injection Molding Services

- Tolerance: ±0.01mm

- Inspection: CMM, Projector, Caliper, Microscope, Etc.

- Design Software: UG, Pro/E, AutoCAD, Solidworks

- CNC Machining: Yes

- Additional Keywords: Thermosetting Molding Service, Injection Moulding Service, Thermoplastic Molding Service

Support and Services:

Our Product Technical Support and Services for Injection Molding Services include:

- Assistance with machine setup and calibration

- Troubleshooting technical issues related to injection molding processes

- Providing guidance on material selection and process optimization

- Offering training programs for operators and maintenance staff

- Continuous support and consultation to ensure optimal performance of the injection molding equipment